Ingenious Foam Control Solutions to Enhance Your Production Processes

Ingenious Foam Control Solutions to Enhance Your Production Processes

Blog Article

Recognizing the Significance of Foam Control in Industrial Processes

In industrial processes, foam control is often a neglected yet essential element that directly affects operational efficiency and product integrity. The presence of too much foam can bring about substantial challenges, consisting of interfered with blending and lessened reaction kinetics, which might inevitably affect product quality across various markets such as pharmaceuticals and food manufacturing. Recognizing the subtleties of foam management, including effective techniques and potential improvements, elevates essential questions regarding ideal practices and future technologies. What are the implications for industries striving for boosted performance and compliance?

The Function of Foam in Sector

Foam plays a considerable duty in numerous industrial procedures, affecting both effectiveness and item quality. In markets such as food and beverage, drugs, and petrochemicals, foam can serve both helpful and harmful objectives. In the food sector, foam stablizing is crucial throughout processes like whipping lotion or generating beer, where the top quality of foam directly affects consumer understanding and item characteristics.

In chemical production, foam can serve as an obstacle, preventing the proper blending of reagents, which can lead to incomplete reactions and suboptimal returns. Alternatively, in processes like flotation protection in mineral handling, foam is utilized to divide beneficial minerals from waste product, improving recuperation prices.

In addition, in wastewater therapy, foam development can indicate the presence of raw material, acting as a vital criterion for procedure tracking. The capacity to control foam is important for preserving procedure stability and enhancing operational prices. Understanding the duty of foam in industrial applications enables designers and operators to apply effective foam management methods, guaranteeing that foam adds positively to total procedure performance while minimizing its potential downsides.

Usual Obstacles of Foam Formation

Lots of sectors face substantial obstacles because of the unintended formation of foam during numerous procedures. Foam can interfere with the effectiveness of procedures, resulting in increased downtime and higher operational expenses. In sectors such as drugs, food and beverage, and wastewater therapy, foam can hinder blending, decrease product yield, and complicate splitting up processes.

In addition, foam can create security dangers by obstructing clear visibility, which is vital in atmospheres where exact dimensions and tracking are needed. The presence of foam can also bring about devices damages, as too much stress build-up may happen in containers and reactors.

Additionally, the demand for constant intervention to manage foam can divert sources and labor, eventually affecting efficiency. Environmental guidelines pose another difficulty, as extreme foam can bring about non-compliance issues in effluent discharge, demanding extra therapy processes.

Effect On Product Quality

In chemical production, foam can hinder reaction kinetics by restricting gas-liquid get in touch with, resulting in incomplete reactions and reduced returns. This not only impacts the effectiveness of production yet can also lead to low-grade final result that do not fulfill regulative requirements or consumer requirements.

In addition, in pharmaceuticals, foam development throughout formulation processes can present air bubbles into sensitive substances, jeopardizing medication effectiveness and stability. On top of that, foam can create operational issues such as overflow and devices malfunctions, boosting downtime and maintenance expenses, additionally impacting item quality and consistency.

Strategies for Effective Foam Control

Attending to the challenges posed by foam is essential for maintaining item top quality across numerous industrial sectors. Reliable foam control techniques are important to reduce the unfavorable results of foam formation, which can interfere with operations and compromise item stability.

One of the main techniques entails the choice and application of appropriate antifoaming agents. These representatives are developed to decrease surface area tension and inhibit bubble development, and their effectiveness can differ based on the certain procedure conditions. Routine tracking of foam degrees is vital to make sure timely intervention, allowing operators to use antifoaming agents prior to foam comes to be a considerable issue.

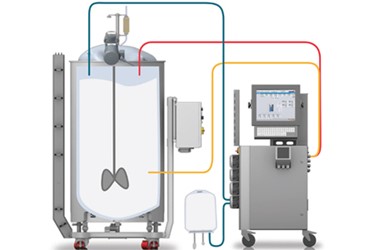

Additionally, maximizing process criteria such as temperature and agitation can play a critical role in foam management. Minimizing agitation strength or adjusting feed prices can decrease foam generation. Executing mechanical foam control tools, such as foam breakers or defoamers, can also give efficient solutions for high-foaming applications.

Training employees on foam monitoring strategies and the significance of maintaining optimal operating conditions further boosts foam control initiatives. Foam Control. By using a mix of these methods, sectors can effectively handle foam, ensuring functional efficiency and maintaining the quality of their items

Future Trends in Foam Management

How will innovations in innovation form the future of foam management in commercial processes? The assimilation of man-made knowledge (AI) and equipment learning will transform foam control strategies, allowing real-time surveillance and adaptive actions to foam basics development. These technologies can examine historical data and functional parameters to forecast foam habits, permitting preemptive you can try here steps that enhance procedure efficiency.

Additionally, the development of advanced foam control representatives, consisting of bio-based and eco-friendly alternatives, is gaining traction. These technologies not just reduce foam yet likewise align with sustainability goals, lowering the eco-friendly impact of industrial operations.

Automation will certainly also play an essential role, as automated foam control systems can enhance the dose of defoamers based upon real-time measurements, minimizing waste and improving effectiveness.

Additionally, the fostering of IoT (Web of Things) gadgets will certainly assist in seamless interaction in between devices and foam control systems, guaranteeing a holistic strategy to foam management. (Foam Control)

Verdict

Finally, reliable foam control is important for enhancing commercial processes across various industries. The difficulties presented by foam development can dramatically affect product high quality and operational effectiveness. Applying critical foam administration techniques, consisting of the use of antifoaming representatives and process optimization, reduces these difficulties. As industries remain to progress, continuous improvements in foam control technologies will certainly even more enhance performance and sustainability, making certain conformity with ecological guidelines while maintaining the integrity of items.

In the food market, foam stablizing is critical throughout procedures like whipping cream or generating beer, where the high quality of foam straight influences consumer perception and item qualities.

Recognizing the role of foam in commercial applications allows designers and operators to carry out efficient foam administration strategies, ensuring that foam contributes positively to overall procedure performance while lessening its prospective disadvantages.

Routine tracking of foam degrees is essential to make sure timely intervention, enabling drivers to use antifoaming agents before foam comes to be a substantial concern.

Carrying out mechanical foam control devices, such as foam breakers or defoamers, can likewise provide efficient remedies for high-foaming applications.

The combination of man-made knowledge (AI) and equipment knowing will certainly reinvent foam control approaches, enabling real-time tracking and adaptive actions to foam formation.

Report this page